SSME Series Electromagnetic Compatibility Metal Wa

Category: Metal Cable Gland

Product Overview

Material: The outer metal is brass nickel-plated; the inner core sleeve is nylon; the seal material is nitrile rubber

Protection level: within the specified Clamping range, using appropriate O-rings, the protection level can reach IP68

Temperature range: static: -40 ℃ to + 100 ℃, can reach + 120 ℃ in a short time

Dynamic: -20 ℃ to + 80 ℃, can reach + 100 ℃ in a short time

Application occasions: occasions that require electromagnetic compatibility, suitable for electrical control equipment and electronic equipment.

Note: The connector products that pass the ROHS certification can be customized according to customer needs

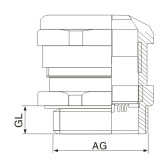

Structure Chart

Technical Parameter

SSME-M Metric Thread

| Artice no. | Thread Dimension(mm) | Clamping range(mm) | Thread AG(mm) | GL(mm) | Wrench size(mm) | Packet units |

| SSME-M12 | M12*1.5 | 3~6.5 | 12 | 5 | 14 | 50 |

| SSME-M16 | M16*1.5 | 4~8 | 16 | 7 | 18 | 50 |

| SSME-M18 | M18*1.5 | 5~10 | 16 | 7 | 20 | 50 |

| SSME-M20 | M20*1.5 | 6~12 | 20 | 7 | 22 | 50 |

| SSME-M22 | M22*1.5 | 8~14 | 22 | 7 | 24 | 50 |

| SSME-M24 | M24*1.5 | 8~14 | 24 | 7 | 27 | 50 |

| SSME-M25-X | M25*1.5 | 10~16 | 25 | 7 | 28 | 25 |

| SSME-M25 | M25*1.5 | 13~18 | 25 | 7 | 28 | 25 |

| SSME-M30 | M30*2.0 | 13~18 | 30 | 8 | 34 | 25 |

| SSME-M32-X | M32*1.5 | 15~22 | 32 | 8 | 36 | 12 |

| SSME-M32 | M32*1.5 | 18~25 | 32 | 8 | 36 | 12 |

| SSME-M36 | M36*2.0 | 18~25 | 36 | 8 | 40 | 9 |

| SSME-M40 | M40*1.5 | 21~28 | 40 | 9 | 46 | 5 |

| SSME-M48 | M48*2.0 | 22~32 | 48 | 9 | 55 | 1 |

| SSME-M50 | M50*1.5 | 32~38 | 50 | 9 | 55 | 1 |

| SSME-M56 | M56*2.0 | 32~38 | 56 | 9 | 60 | 1 |

| SSME-M63 | M63*1.5 | 37~44 | 63 | 10 | 70 | 1 |

SSME-PG Thread

| Artice no. | Thread Dimension(mm) | Clamping range(mm) | Thread AG(mm) | GL(mm) | Wrench size(mm) | Packet units |

| SSME-PG7 | PG7 | 3~6.5 | 12.5 | 5 | 14 | 50 |

| SSME-PG9 | PG9 | 4~8 | 15.2 | 7 | 17 | 50 |

| SSME-PG11 | PG11 | 5~10 | 18.6 | 7 | 20 | 50 |

| SSME-PG13.5 | PG13.5 | 6~12 | 20.4 | 7 | 22 | 50 |

| SSME-PG16 | PG16 | 8~14 | 22.5 | 7 | 24 | 50 |

| SSME-PG21 | PG21 | 13~18 | 28.3 | 8 | 30 | 25 |

| SSME-PG29 | PG29 | 18~25 | 37 | 8 | 40 | 12 |

| SSME-PG36 | PG36 | 22~32 | 47 | 9 | 50 | 5 |

| SSME-PG42 | PG42 | 32~38 | 54 | 9 | 60 | 1 |

| SSME-PG48 | PG48 | 37~44 | 59.3 | 10 | 65 | 1 |

Specific Use

Do away with one small section of the outer sheath of the screened cable,and cut off the shield layer,turn over the conductor of the shield layer and wrap it outside the seal,the length of it should be longer than the position of the sealing ring,then put into the cable gland and revolve it tightly.We suggest scraping the paint contacted to the cable gland and the thread to guarantee the good electric conductivity.